In recent years, the plastic shell of switching power supply has been widely used. The emergence of the plastic shell of switchi…… MORE

The power supply plastic shell has been quite active in our life. Take our common mobile phone charger shell as an example, its …… MORE

Injection molding is a specific cycle. There are five factors that affect injection molding: temperature, speed, pressure, posit…… MORE

What should be considered when choosing a manufacturer for injection molding? Injection molding products are used in many fields…… MORE

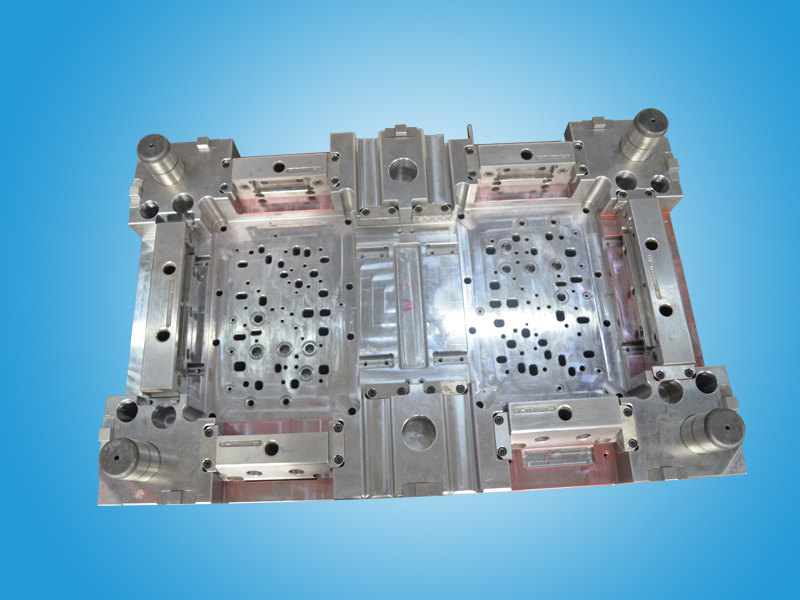

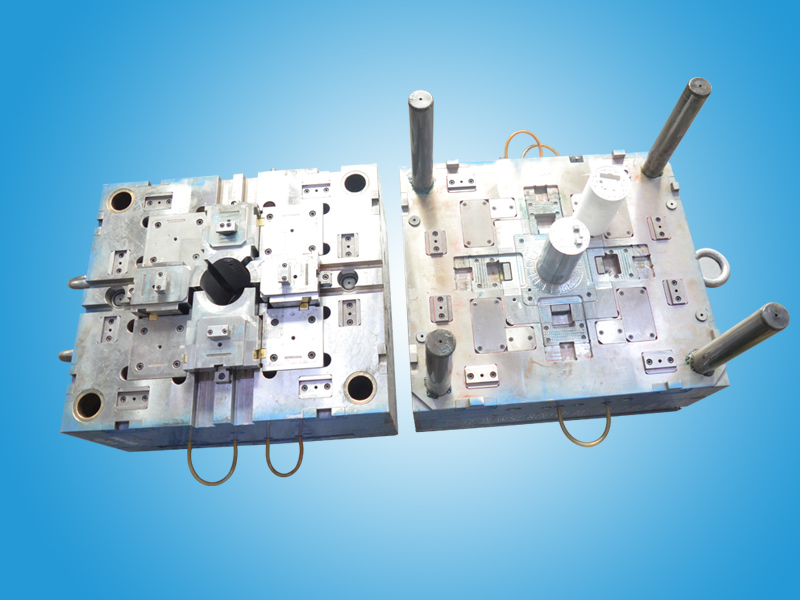

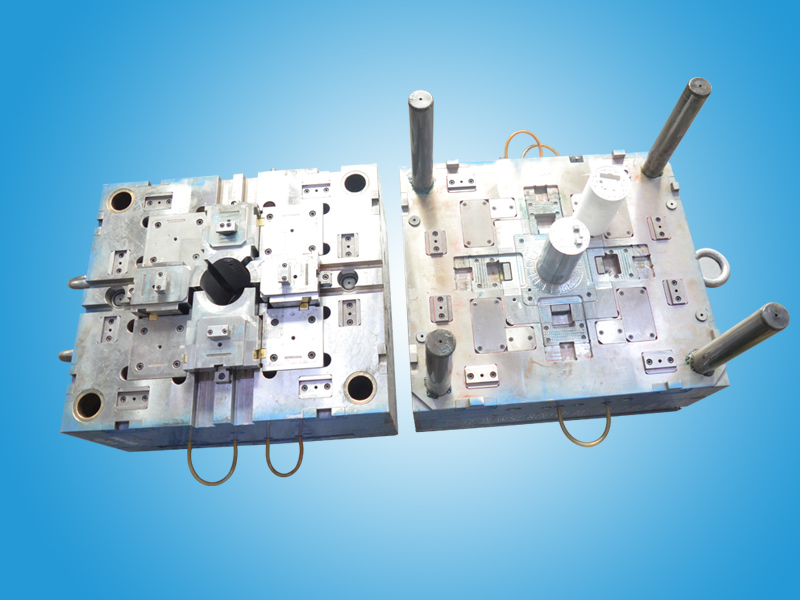

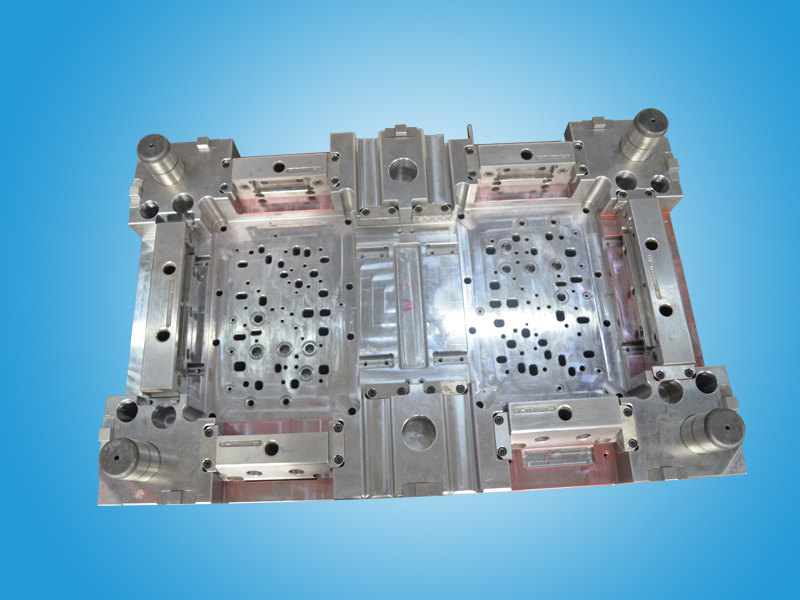

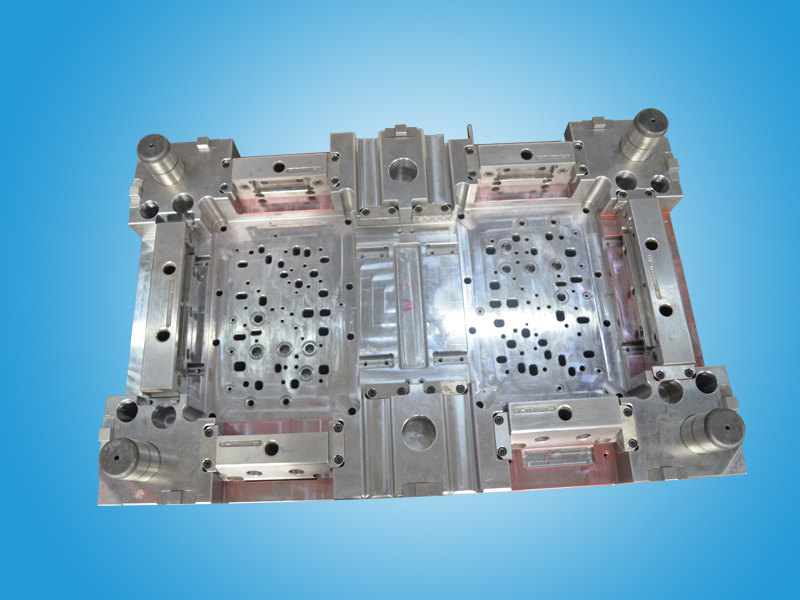

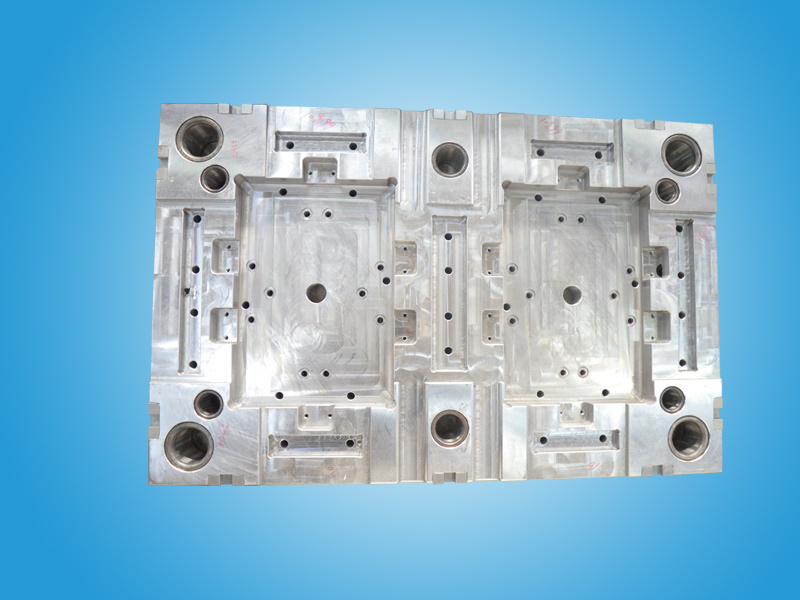

The accuracy of plastic injection mold processing determines the accuracy of plastic parts, so it is very important to control t…… MORE

Multi material injection molding is to integrate a variety of plastic materials with different characteristics to improve the ad…… MORE

1、 Light weight led waterproof power supply plastic shell is a relatively light material, with a relative density of 0.90~2.2. O…… MORE

At present, the proportion of plastic mold in the whole mold industry is about 30%, and the proportion in mold import and export…… MORE

療器材類/檢測儀外殼3.jpg)

In the process of processing medical device shells, the first thing to do is to blanking them. When good blanking is achieved, t…… MORE

1. Shrinkage in injection molding is a common problem in injection molding, especially for plastic products with high surface qu…… MORE

Our friends in the production line know that there are some operating rules for injection molding, and we should know that safet…… MORE