廢料本質(zhì)上是形狀孔的反面圖像。也就是說(shuō),同樣的位置在相反的位置。通過(guò)檢查廢料,塑膠外殼模具可以判斷上下模具的間隙是否正確。 如果塑膠外殼模具的間隙過(guò)大,廢料會(huì)呈現(xiàn)粗糙、起伏的斷裂表面和狹窄的亮帶區(qū)域。塑膠外殼模具間隙越大,斷裂形成的角度越大,亮帶的面積越大。如果間隙過(guò)小,則廢料將呈現(xiàn)出來(lái)的小角度的斷裂表面……

MORE療器材類/檢測(cè)儀外殼.jpg)

(1) Geometry and accuracy. The geometric dimension of the blister shell includes the dimension from the cutting surface to the f…… MORE

The manufacturer of the medical device shell selects the thick sheet Blister processing technology to improve the product perfor…… MORE

The manufacturing process of deep hole drilling is widely used in the processing of injection molds. This method requires a spec…… MORE

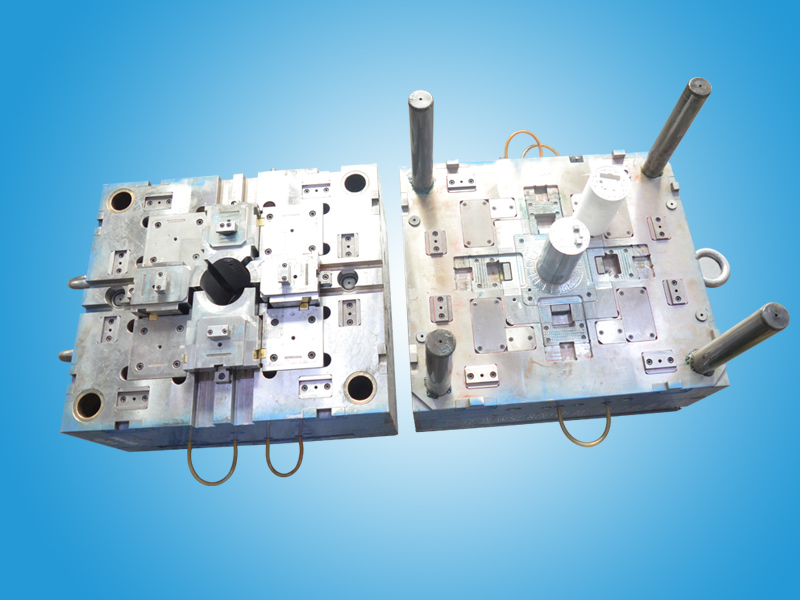

1、 The design basis of plastic mold, dimensional accuracy and the accuracy of related dimensions, and the specific requirements …… MORE

General purpose plastics general purpose plastics refer to those plastics that are mainly used for mass production of a large nu…… MORE

一.塑膠料的特征 1.塑膠料具有質(zhì)輕、比強(qiáng)度高、不銹蝕、絕緣性好、加工性好、加工本錢低、適合大批量消費(fèi)等優(yōu)點(diǎn),塑膠料在家用電器中的應(yīng)用有著非常重要的作用。 2.據(jù)報(bào)道,近年美國(guó)度電的塑料耗費(fèi)量占其總塑料耗費(fèi)量的4.7%,而日本家電塑料耗費(fèi)量更占到其總塑料耗費(fèi)量的12.3%。我國(guó)由于是家電大國(guó)……

MORE

塑膠外殼披鋒又稱飛邊、溢邊、溢料等,大多發(fā)作在塑膠外殼模具的分合位置上,如:模具的分型面、滑塊的滑配部位、鑲件的縫隙、頂桿的孔隙等處。溢料不及時(shí)處理將會(huì)進(jìn)一步擴(kuò)展化,從而壓印塑膠模具構(gòu)成部分陷塌,形成永世性損傷。塑膠模具鑲件縫隙和頂桿孔隙的披鋒還會(huì)使塑膠外殼品在模上,影響脫模。 塑膠外殼披鋒本質(zhì)上是塑膠原……

MORE療器材類/減肥儀器殼.jpg)

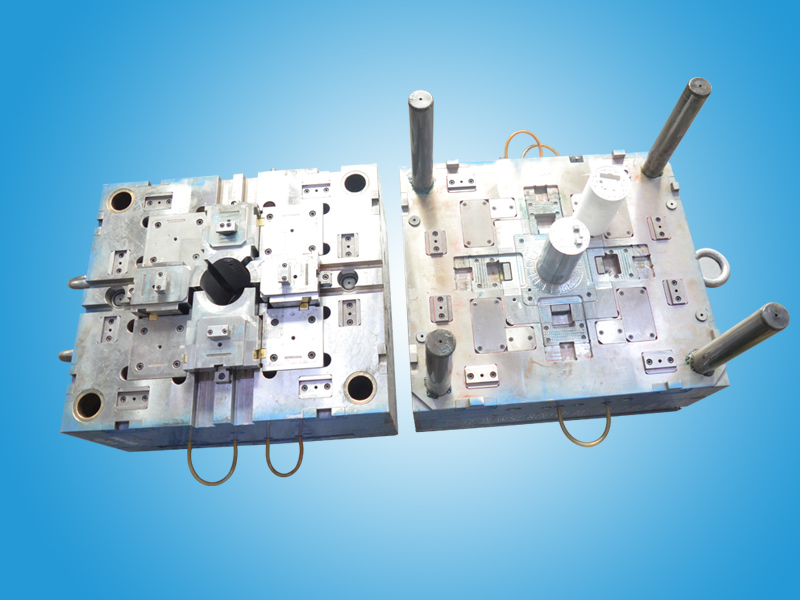

Plastic mold is the abbreviation of combined plastic mold, which is used for compression molding, extrusion molding, injection m…… MORE

1. Mold blank preparation. Most die blanks are metal, taking destruction processing as an example. The raw materials for forging…… MORE

療器材類/檢測(cè)儀外殼.jpg)

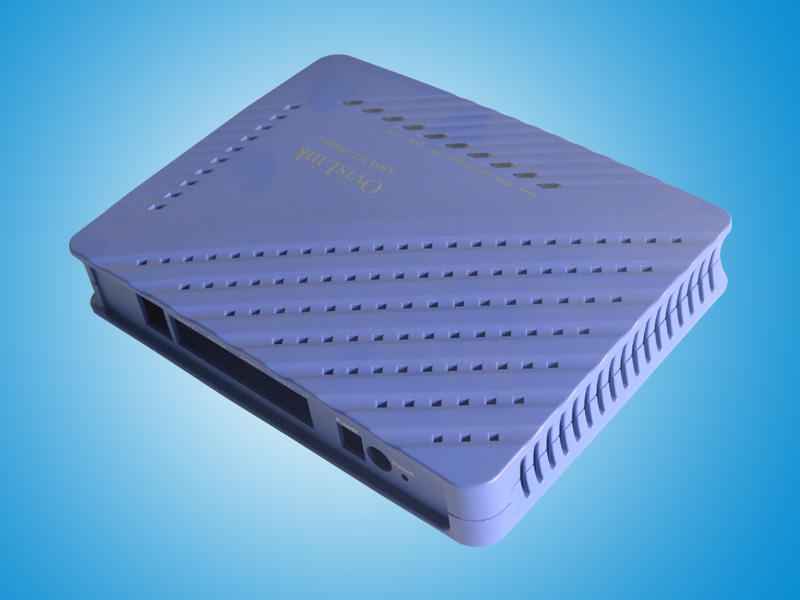

醫(yī)療器械外殼是醫(yī)療機(jī)械領(lǐng)域中不可或缺的一部分。作為醫(yī)療器械的重要組成一部分,在整個(gè)制造和運(yùn)用過(guò)程中有很多的大部分關(guān)鍵環(huán)節(jié)。 機(jī)箱在設(shè)計(jì)和運(yùn)用案例的時(shí)候,應(yīng)考慮到其受到磁場(chǎng)地理環(huán)境的影響狀況。它是因?yàn)闄C(jī)箱在整個(gè)運(yùn)用的過(guò)程中會(huì)遇到很多的醫(yī)療器械,這類醫(yī)療器械本身也會(huì)受到磁場(chǎng)地理環(huán)境的影響。所以在方案設(shè)計(jì)機(jī)箱的……

MORE備/監(jiān)控器1.jpg)

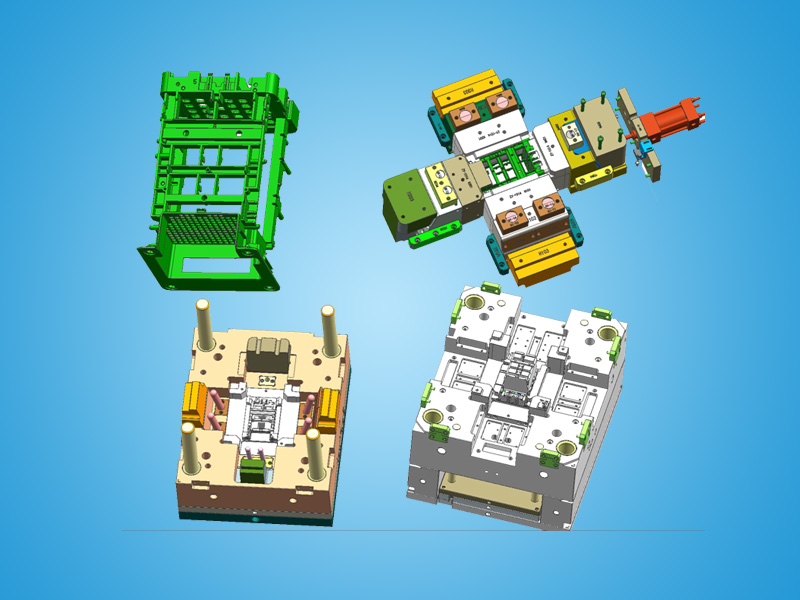

At present, some cooperative customers are making security camera shell products. Some customers say that the injection color is…… MORE